|

From the Home Page of the ACT, click on the left link "Experiments"

to view the list of remote processes availables for control. For each process it

is provided a "System Description" link in which a mathematical

model of the process is given. This model can be useful to better understand how

the process works, and to allow a user to design a control law.

The Automatic Control Telelab allows a user to execute 3 kinds of remote

experiments:

Control Experiment using a Predefined

Controller

Once chosen the remote process on which perform the experiment, click on "Control

Experiment"; a new page (Control Type Interface) will be loaded (see Figure 1).

Control Type Interface

Figure 1 - The Control Type Interface

Now it is requested to fill a form

regarding some personal data (Name, Country and Email address). This data

will be used for statistical purpose.

Under the personal data panel, one or more predefined

controllers are displayed. The Simulink models representing such

controllers can be downloaded by the "Download Model"

link.

To run the experiment using a predefined controller

just click on "Run Experiment". A new interface (Experiment

Interface) will

appear (Figure 2).

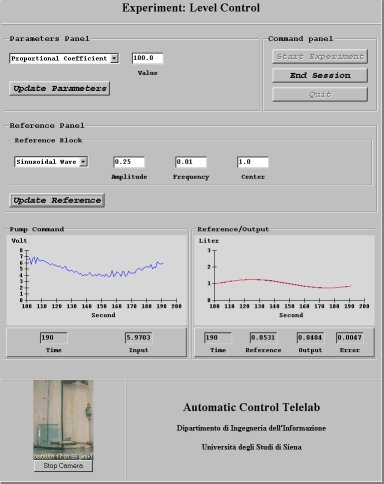

Experiment Interface

This interface is divided in 5 parts:

(1) Command Panel

(2) Controller Parameters Panel

(3) Reference Panel

(4) Experiment Dynamics Window

(5) Live Video Window

Figure 2 - The Experiment Interface

(1) Command Panel: This panel contains only 3 buttons which allow to start the

experiment, to stop it or to quit (before running the experiment).

(2) Controller Parameter Panel: In this panel, the typical parameters of the controller

are displayed. The user can modify them and send the new values to the server just

pressing the " update parameters" button.

(3) Reference Panel: This section gives the user the opportunity to choose the reference

signal among a set of possible choices.

(4) Experiment Dynamics Window: To monitor the dynamics of the process,

some graphical and numerical panels are provided. The number of these panels will change

with the number of inputs and outputs of the process. For a SISO process (like in Fig. 2) there is a panel for the input

(command) and a panel for the reference and the output. These graphics are updated every second.

(5) Live Video Window: In this part, a live video of the experiment is

shown.

Once stopped the experiment (by the user, the time-out or the safety system),

the user can download the file containing the detailed dynamics of the experiment in Matlab format (.mat). This information can be useful for

off-line analysis.

Control Experiment using a User-defined

Controller

Once chosen the remote process on which perform the

experiment, click on "Control

Experiment"; a new page (Control Type Interface) will be loaded (see Figure 1).

The only difference with respect to the predefined

controller is that now, to run an experiment, it is needed to upload to the

server a Simulink model which implements the user controller.

To know how to design a controller click

here.

In the Control Type Interface (Fig. 1) it is needed to

fill the field "Controller Model" choosing the Simulink model

file (.mdl) of the controller. If such controller needs some workspace variables

to work, it is possible to set the Matlab Workspace file in the "Controller

Data" field.

Then it is required to set the sample time to be used. If the controller is continuous time, sample time is intended as the

integration step of the Simulink solver.

From this interface it is also possible to download a

Simulink model which describe the selected process. So it is possible to

simulate the controller behaviour before using it on the real experiment.

It is now possible to send the controller to the server by

means of the "Send Controller" link. The controller is

then compiled and if no errors occur, the "Experiment Interface"

is displayed (Fig. 2). Then the experiment follows the steps described

previously.

Student Competition Experiment

Student Competition differs from the control experiment

descrived above, since now it is required that a user-defined controller must

satisfy certain performance specifications. Controllers are then evaluated and

ranked.

To access to the competition, from the "Experiment

page" (or the shortcut "Competitions" in the left frame), just

click on the "Student Competition" link (note that not all

processes have this link). It now possible to see all the competitions about the

chosen process. For each competition it is possible to view a brief description

as well as a complete description (pdf file) of the competition.

Through the "Show Ranking" link it is

possible to view all the controllers regarding that competition. For each

controller it is then possible to see some general data and a time plot of the

experiment. Moreover it is possible to download your own controllers.

To partecipate to the competition just click on "Try a

Controller". Then it is needed to login, since only registered users can

compete. For new users, a special form regarding personal data is provided.

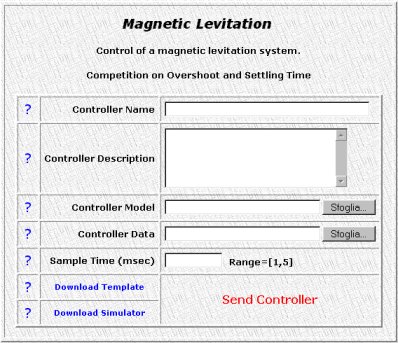

Once logged in, the Interface shows in Figure 3 appears. This

Interface is similar to that described in Figure 1, but here it is required also

to give a name and a description at your controller. Rules about how to write a

controller are the same as for user-defined controllers (how to design a

controller).

Figure 3 - The Competition Interface

Also in this case it is possible to download a

"Simulator", to test the controller before using it on the actual

plant.

Once sent the controller ("Send Controller"),

if everything is ok, an interface similar to that shown in Figure 2 appears, but

without the Controller Parameter Panel and the Reference Panel. In fact, it is

not allowed to change anything during the competition experiment. To run the

competition just press the "Start Experiment" button.

At the end of the competition the experiment is automatically

stopped, and the performance indexes computed. If such indexes are satisfy, an

overall index is computed and the controller put in the ranking.

If during the experiment the system becomes unstable, it is

automatically stopped and no index is computed.

There is a maximum number of controllers that each user can

do; over that bound it is requested to delete one.

How to design a controller model

Software requirements:

Matlab 5.0 (or higher) and Simulink.

How to Design a Controller:

Design a Simulink model of your controller according to limitations described below. For the user convenience, a template model can be downloaded from the server.

This Simulink model contains two subsystems (only one for Student Competition

Template), which refer to the controller and the reference as well. You have just to connect the input and output blocks contained in it with the blocks which implement the controller.

To insert an on-line tuning parameter (not allowed for Student Competition), you must label a block in this way:

ACT_TP_parameter name (E.g. ACT_TP_Proportional Coefficient)

In this case, you will be able to modify the parameter while the experiment is running. You can do this only for constant blocks and gain blocks. Any other block

may not be recognized properly.

Limitations:

To design a Simulink controller model you cannot use Simulink blocks containing Matlab functions and S-functions.

|